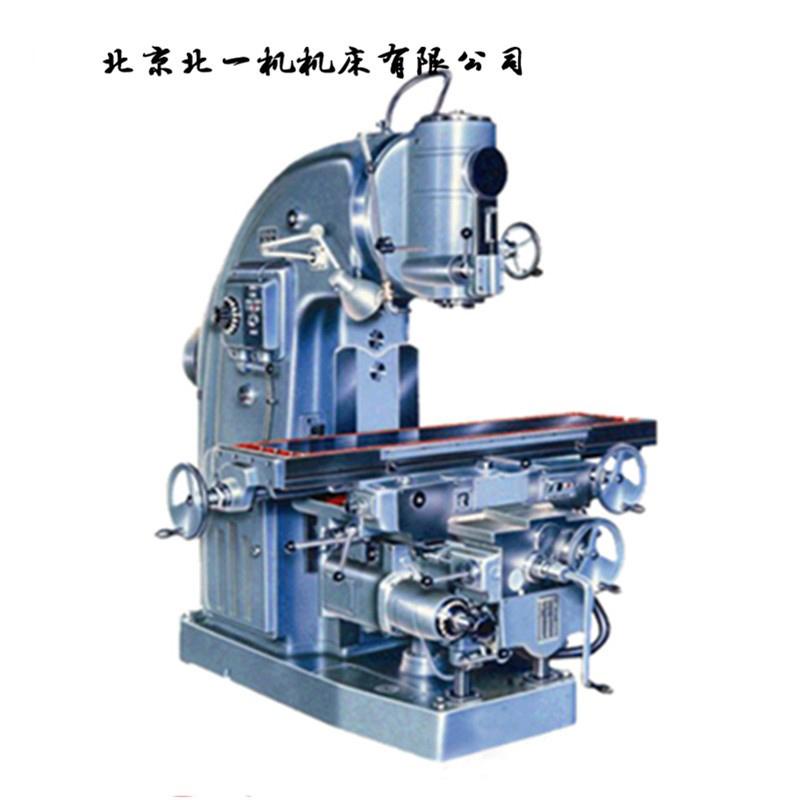

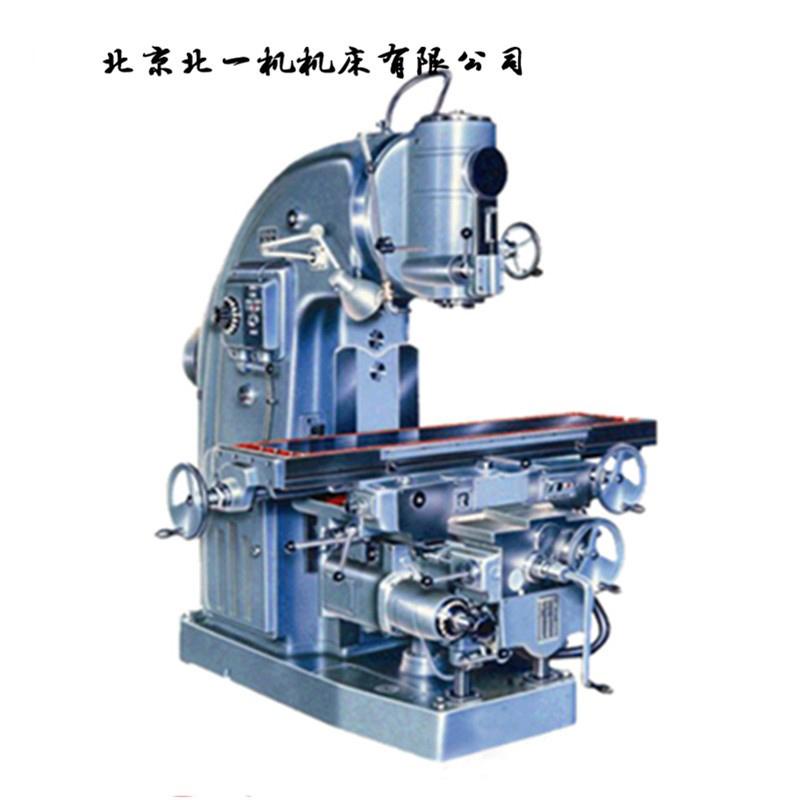

B1-400K vertical lifting table milling machine is a modified product based on the original X53K vertical milling machine in our factory.X53k has won the title of "Quality Trustworthy Product" issued by the Ministry of Machinery Industry.The product is reliable in structure, good in performance, stable in quality and easy to operate. It is suitable for all kinds of mechanical processing, and can process various planes, grooves, gears, etc.Equipped with milling machine accessories such as round table and indexing head, the scope of use of the machine tool can be further expanded.XA5040 vertical lifting table milling machine accurately controls the size of parts, improves precision and production efficiency.It is suitable for milling planes, slopes, grooves, etc. with various rod milling cutters, round milling cutters, and angle milling cutters.The machine tool has enough rigidity and power to perform high-speed cutting and heavy-duty cutting work.Structural and performance characteristics: The structure of the machine tool is rigid and can withstand heavy-duty cutting; the machine tool spindle motor has high power and a wide range of speed changes, giving full play to the performance of the tool and capable of high-speed cutting. High-quality alloy steel is used to ensure the durability and stability of the machine tool; the machine tool has a complete lubrication system.XA5040 random accessories: end mill mandrel, mandrel wrench, Morse taper intermediate sleeve, milling machine pull rod, various wrenches, oil gun, anchor screw, pad iron.Special accessories (separately priced): indexing head, disc table, vise, milling chuck, milling cutter disc.Color: European Green (Standard) Machine Gray (Optional) Workbench: 400'2000, 400'2200 (Optional) Bed Height: 150, 200, 250 (Optional) Digital Display (Optional) Vertical Milling machine-type unit XA5032 B1-400K Workbench (width*length) mm 320*1325*1700 400*1700/2000/2200 Maximum load capacity kg 500 800 Number of T-slots 3 3 T-slot width mm 18 18 T Groove spacing mm 70 90 X-direction (longitudinal stroke) manual/motorized mm 700/680, 1100/1080 900/880, 1200/1180, 1380/1360 Y-direction (transverse stroke) manual/motorized mm 255/240 315/300 Z-direction (vertical of lifting platform) manual/motorized mm 370/350 385/365 taper hole 7:24 (ISO No.50) 7:24 (ISO No.50) speed range r/min 30-1500 30-1500 speed Series level 18 18 Axial movement distance mm 85 85 Larger rotation angle ±45o ±45o Minimum/maximum distance from spindle end surface to worktable surface mm 45/415 30/500 Distance from bed vertical guideway surface to worktable centerline mm 350 450 Cutting feed speed mm/min X:23.5-1180 Y:23.5-1180 Z:8-394 X:23.5-1180 Y:23.5-786 Z:8-394 Rapid traverse speed mm/min X:2300 Y:2300 Z:770 X:2300 Y:1540 Z:770 Feed level 18 18 Spindle motor power kw 7.5 11 Feed motor power kw 2.2 3 Machine tool dimensions (length*width*height) mm 2295*1770*2094 2556* 2159*2258 Machine weight kg 2800 4250