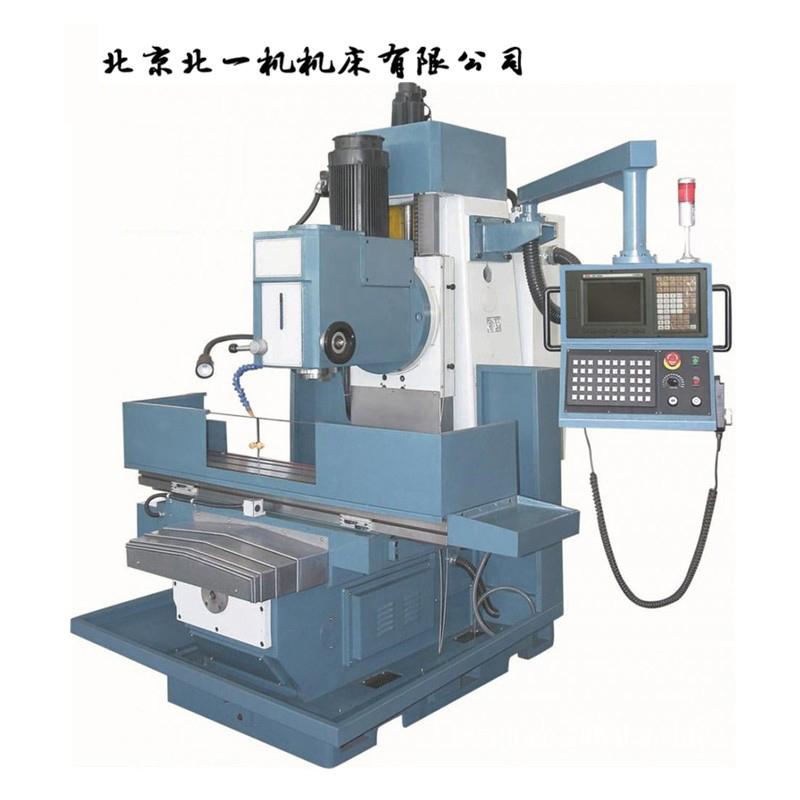

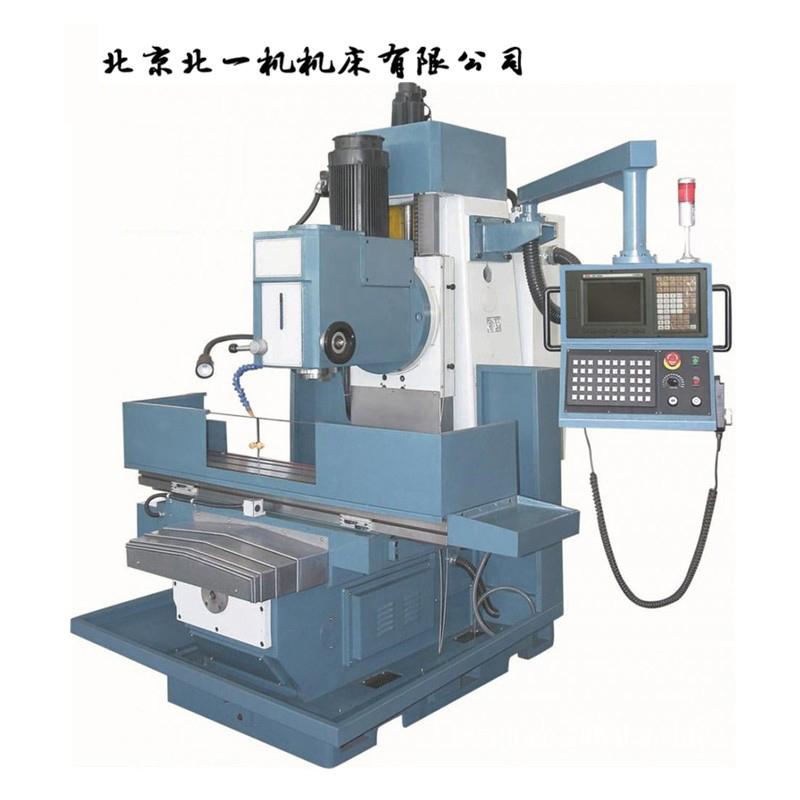

The product for the X, Y, Z three and a half shaft servo control closed loop vertical CNC lathe bed milling machine, three axis are rectangular quenching hardened rail, guide rail, large span, wide is compact and reasonable structure and dimension. Can be achieved for a variety of plate, plate and shell, a complex parts, such as CAM, mold clamping, can complete drilling, milling, boring, expansion, hinge and so on a variety of machining, suitable for many varieties, medium and small batch production of products, can meet for complex, high precision parts processing. Is machinery manufacturing, mold, instruments, meters, automobiles, motorcycles, and other industries ideal processing equipment.

Can match the fourth axis of rotation, in order to meet the processing requirements of special parts.

1, base, sliding seat, table, column, spindle box foundation with cast iron HT300, and the artificial aging treatment, ensure the stability of the machine tool use for a long time, has provided the safeguard for the stability of the machine tool performance.

2, the overall structure of lathe bed type structure, mechanical speed and high precision milling head for high-power milling head, milling head can work within the scope of 30 ° left and right; The spindle sleeve feeding with automatic, manual, manual fine tuning, etc; The spindle rigidity, speed regulation is convenient and flexible.

3, X, Y, Z three directions of feed adopt high precision, high strength, ball screw, servo motor drive, to ensure the positioning precision of machine tools. Protective device for the guide, ball screw, ensure the cleanness of lead screw and guide rail, to ensure that the machine tool transmission precision and operation.

4, workbench to travel up to 1000 mm X, Y, Z direction guide are wide rectangular slide guide, and the super audio quenching and precision grinding. Slide guide surface precision lapping, with automatic forced lubrication, reduce feed movement of the friction resistance, reduce the low speed crawl, improve the accuracy of machine tool life.

5, machine tool operation system can complete arbitrary Angle of straight line, arc and high precision milling, drilling and tapping can be performed. Rich in NC functions; Such as color LCD display, all kinds of circular function, the cutting tool compensation, program storage and editing, 3 d graphic simulation of machining track, etc. Not only is suitable for the user strong milling processing; Procurement is also teaching ideal equipment.

6, lubricating device for vertical, horizontal, vertical screw and guide rail were forced lubrication, reduce machine wear, consumption of machine tools; At the same time, the cooling system through adjusting nozzle changes the size of the cooling fluid flow, meet different processing requirements.

7, machine tool operating system through the arm hanging at the top right of the machine tool, accord with human body engineering principle, easy to operate; Operation panel using the visual symbol design, simple and intuitive.

CNC milling machine - technical parameters

1, the spindle hole taper ISO50

2, the main shaft sleeve 105 mm

3, the spindle end to the work surface from 100 ~ 600 mm

4, the spindle hole center to lathe bed guide rail surface distance is 580 mm

5, the turning Angle of the spindle box