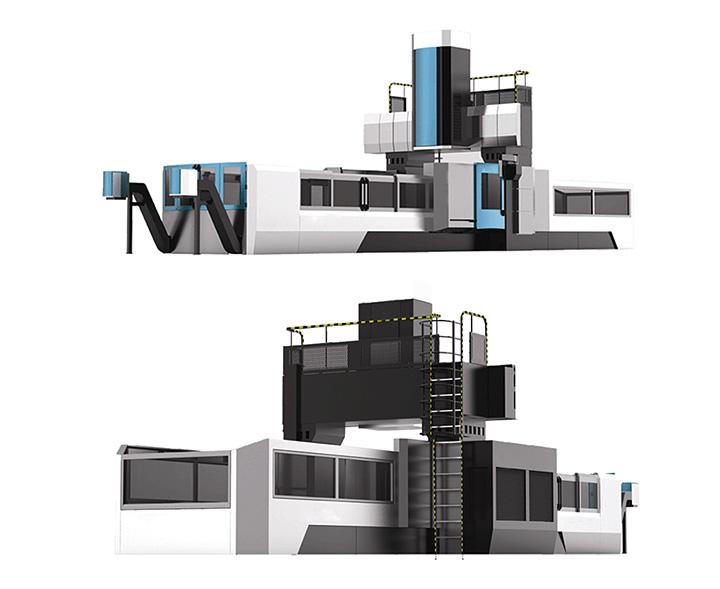

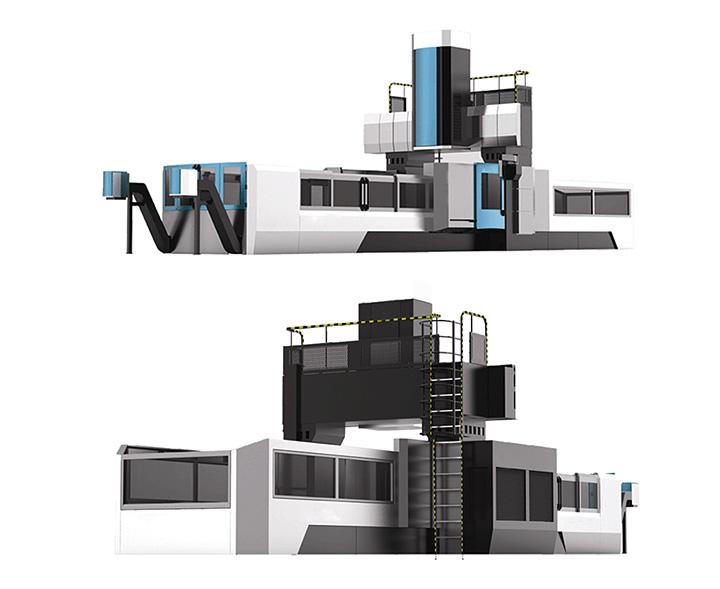

Structure features:

Low 1, base, table, column, beam, slide, spindle box, such as the main basis in cast iron HT300, enclosure structure, compact and reasonable symmetric reinforcement structure to ensure the high rigidity and bending vibration performance; With resin sand molding and after full of aging treatment, provides the guarantee for the stability of the machine tool use for a long time performance.

Low 2, X, Y, Z to guide are Taiwan HIWIN super overloading linear rolling guide, with fast speed, high rigidity, low friction, low noise, low temperature rise change characteristic; X to the two rail line; Y to guide rail USES the stepwise parallel structure, and also give consideration to two guide rail of the vertical and horizontal direction span, has uniform stress, high rigidity, bending torsional advantages: Z to for 350 square ram, wide in the front, left and right direction, respectively is a 55 wide linear guide roller type, operation of high precision, strong rigidity, suitable for strong cutting power.

Low 3, left and right sides of the spindle box each have a balance cylinder, synchronous balance automatically by the gas-liquid conversion device automatically, without external power supply, ensure that the spindle box movement is smooth and stable; Z to the drive motor with a loss of electric braking device;

Low 4, X, Y, Z three directions of feed using high rigid outer loop intubation type double nut preloading P3 large lead ball screw, high feed speed; Drive motor through flexible coupling with screw straight league, feed servo motor directly pass power to high precision ball screw, no gap, ensure the accuracy of the machine tool positioning and synchronization;

Low 5, using Taiwan's professional manufacturer produces, high speed, high precision, high overloading spindle unit rigidity, axial and radial bearing capacity is strong, the spindle is directly connected type spindle, high precision, low noise, high transmission power efficiency can reach more than 98% (reduce power loss in the transmission process), the highest speed is 6000 RPM.

Low 6, main shaft adopts pressure cylinder play knife and center structure, blowing in the spindle blade can effectively unloading the impact on the internal bearing and quickly use center high pressure gas to clean inside the spindle taper, ensure the accuracy of the spindle and the cutting tool and the life;

* 7, X, Y direction protection device for the guide rail, screw, ensure the cleanness of lead screw and guide rail, to ensure the machine drive and motion accuracy and life;

Low 8, the protective outer protective lathe adopts simple and practical structure design, convenient operation, flexible and reliable;

Low 9, using reliable centralized automatic lubricating device, timing quantitative all lubricating points of nc machine tools, automatic intermittent lubrication, lubrication can be adjusted according to working conditions;

Low 10, machine tool operating system on the principle of human body engineering, operation box independent design, can be its own spin, easy to operate.

1. Technical parameters

project

XHAE527 gantry machining center

trip

The X axis workbench moving direction

5200 mm

The spindle slide direction Y

2700 mm

The Z axis

1000mm

The spindle end face to the workbench

200-1000 - mm

Spindle center to guide the post

450mm

A gantry width

2700 mm

feed

The X axis moving fast

12 m/min

Y fast moving

12 m/min

The Z axis moving fast

10 m/min

A cutting feed

1-5000 - mm/min

Work units

Table size (width * length)

2300 x 5000 mm

The largest bearing

13000 kg

Working mesa high from the ground

870 mm

T slot

The 11-28-200 mm

The main shaft

Spindle speed

50-6000 r/min

The spindle taper hole

BT50

X/Y/Z feed motor power

15 (143 nm)

X/Y/Z feed motor

36 (add star reducer) / 36 (add star reducer) / 36 nm

Positioning accuracy

0.03/0.025/0.02 mm

Fine degree of

Repeat positioning accuracy

0.02/0.012/0.012 mm

Its it

Machine weight

55000 kg

2. The CNC control system

Fanuc 0 I MD system has a perfect and reliable interlock alarm, safety protection and fault diagnosis, and other functions, is equipped with a standard RS232 communication interface, can realize DNC machining.

3. The power supply device

Power form three-phase ac 380 v + 10% for 50 hz

40 kva electricity capacity

4. Cooling system

The tank volume: 300 l

Cooling pump power: 180 w

Cooling pump flow: 2 m3 / h

Rated head: 30 m

1. The standard configuration

The serial number

The name of the

brand

place of origin

1

Numerical control system

FANUC 0 I MD with beta motor

Japan

2

Spindle unit

ROM the following Ф 190

Taiwan

3

screw

silver

Taiwan

4

Line rail

Silver (X 3 root 55 wide linear guide roller type, unilateral has six long slider, Y axis 2 root 55 wide linear guide roller type, the Z axis is 350 X 350 square ram, respectively in the front, left, right direction is a 55 wide linear guide roller type

Taiwan

5

Pressure cylinder

The major

Taiwan

6

Electrical appliances

schneider

The French

7

Pneumatic components

Of the DE

Taiwan

8

Nitrogen balance weight

Assist the qing

wuxi

9

Wire rod bearing

Japan NSK

Japan

10

The protective

Whereas haidong539 sheet metal

Shanghai

11

Cooling pump

Fallow and

Taiwan

12

coupling

Mark/R + W

Japan/Germany

13

Lubrication system

River valley

guangdong

2. Select the configuration

The serial number

The name of the

Brand or model

place of origin

1

Spindle oil cooling

The Internet wave

kunshan

2

transmission

ZF or BF

German/Italian

3

Electrical cabinet air conditioner

With the flying

domestic

4

The fourth axis

Xu Yang 320/400/500/630

Taiwan

5

The disc manipulator knife library

Mr Okada BT50 24

Taiwan

3. Machine tool accessories

The serial number

The name says

Specifications or tag

The number of

note

1

Collet chuck the handle

MAS BT40 - ER32-80

1

2

circlip

6, 10, 12, 16, 18, 20

1 each

3

rivet

MAS403 P50T - 1

1

4

Adjustable shim

46 sets of

5

The double helix chip removal device and chain plate chip removal device;