Product Description

GSK RB20 robot application rolling edge loading and unloading

- The hemming of the project must be compatible with a variety of disc parts with a diameter of 80~600mm. The cycle time is 20s if the diameter is <350mm, and the cycle time is 32s if the diameter is >350mm. There is a film on the surface of the product. On-site two processing equipment docking to realize automatic loading and unloading of machine tool processing;

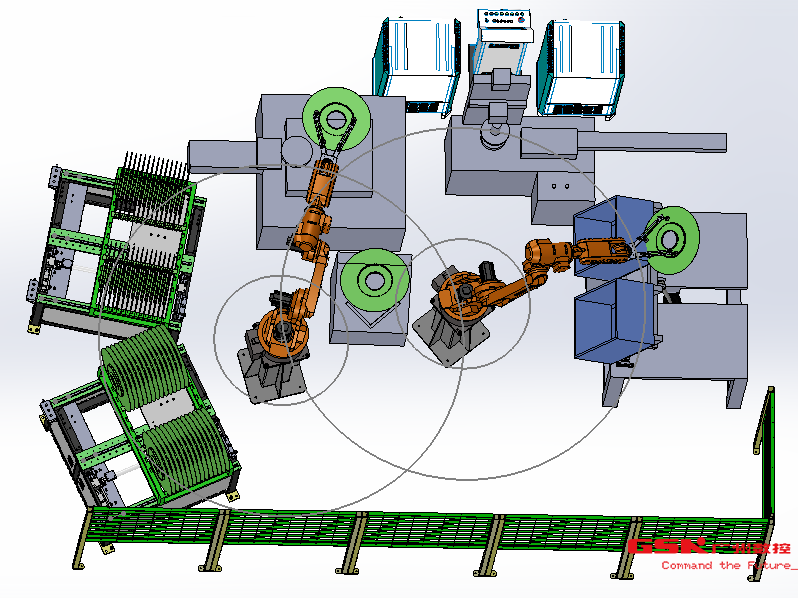

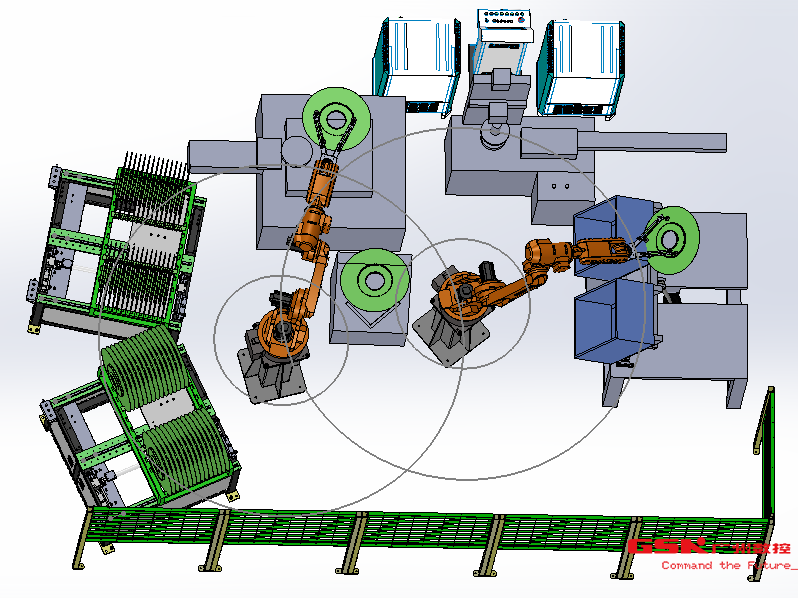

Work object solution

2 sets of hemming equipment and 2 sets of RB20 robots are connected, and a special electromagnet that meets the film adsorption is designed with both hands and a transfer table, so as to realize the rapid pick-and-place parts of the 2 robots at 3 positions; the design of the loading bin The multi-layer translational positioning table can move horizontally when manually changing the model, and the blank loading is simple and convenient; the finished product box is designed with a tilting mechanism, so that the finished product can be directly unloaded into the box by the robot, and the stacking of the box is manually timed pile;

Layout and model application effect

The robot loading and unloading system is easy to change models, the entire robot system has a compact layout, the production cycle is closely matched, and the operation is smooth; the finished product is directly loaded into the finished product box, reducing the loading process and saving labor.

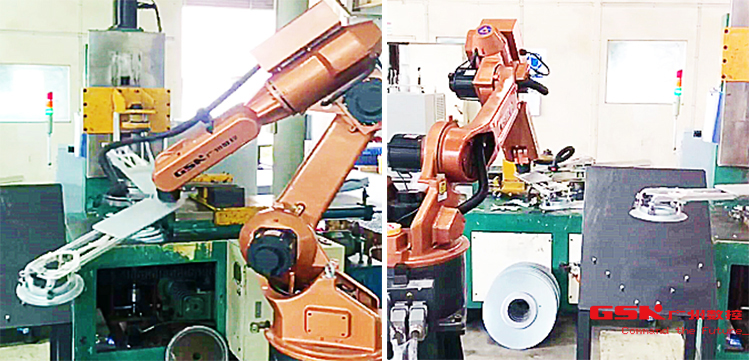

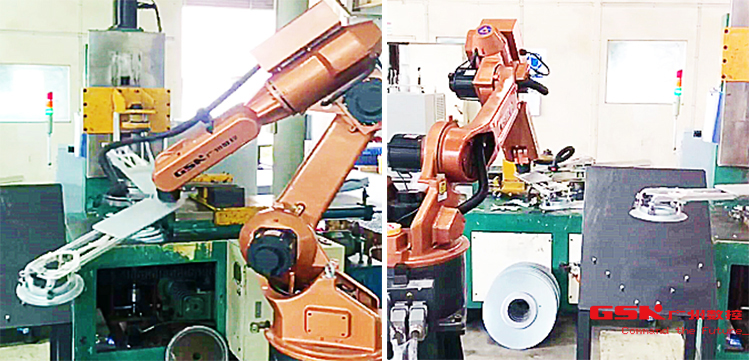

Application site map

Dongguan Hypertron Intelligent Technology Co., Ltd

specializes in the production of special manipulators for injection molding machines and other automation equipment, spot welding robots, handling robots, general-purpose robots, and spraying robots, which can improve automatic productivity, production stability, production efficiency and Quality, and appropriately reduce production personnel, so that the injection molding production plant has a more competitive advantage in the market.The company provides customers with the best overall automation solutions and services from product planning and design, manufacturing, assembly, sales, and service, and is widely used in electronics, communications, automobiles, home appliances and other fields.Provide high-quality, high-efficiency, and reasonably priced automation products for the plastic industry.

Agent for precision CNC lathes CNC milling CNCmachines grinding machines

General items: research and development of intelligent robots; manufacturing of industrial robots; installation and maintenance of industrial robots; sales of industrial robots; sales of intelligent basic manufacturing equipment; manufacturing of intelligent basic manufacturing equipment; manufacturing of industrial automatic control system devices; sales of industrial automatic control system devices; Manufacturing; sales of intelligent instruments and meters; manufacturing of power electronic components; sales of power electronic components; general mechanical equipment installation services; network and information security software development; Import and export of goods; import and export of technology.

Kennethchui Engineer

13715334662

WeChat ID: kennethchui88

Email: everwinmold@163.com

QQ: 2819840570

Product Image