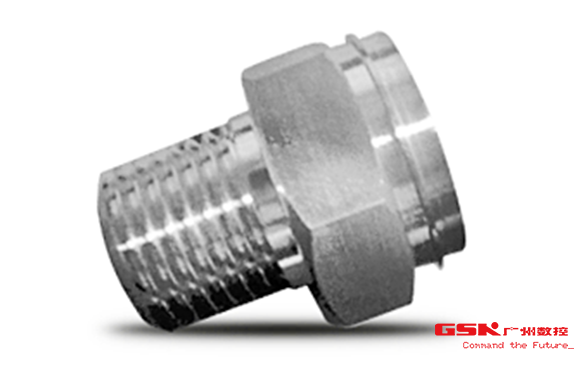

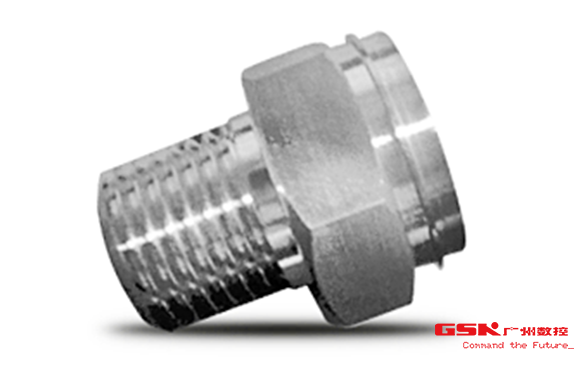

Product Description

GSK RB08 robot application automatic processing of precision pipe joints

- Compatible with a variety of small-batch products to meet the requirements of blister boxes; matching processing technology, docking with 2 processing equipment on site to realize automatic loading and unloading of machine tool processing;

Work object solution

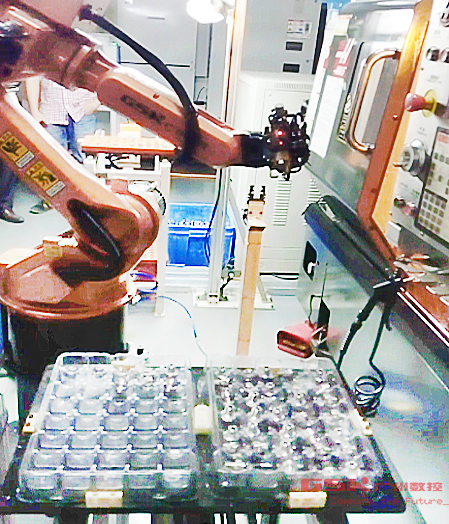

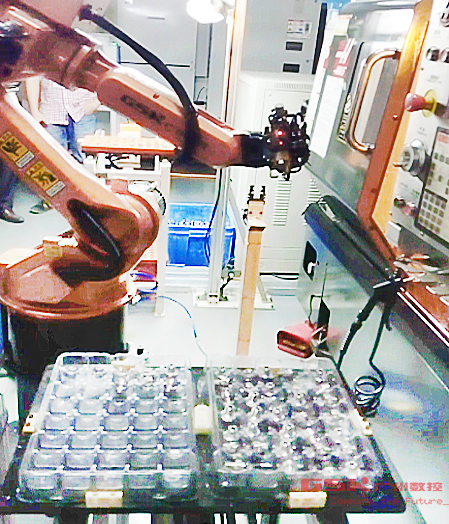

1 RB08 robot, matched with the vision system, to realize precise positioning and grabbing of different incoming blanks; design a set of universal loading tray to meet the rough positioning of different incoming materials, manually place materials randomly, and blank loading is simple , Convenient; Set up the plastic box transplanting mechanism, the robot directly unloads the material to the special blister box, manual timing random inspection and blister box stacking; Set up a set of master control system, matching three sets of cylinder grippers and a general-purpose replacement Direction mechanism, no need to manually adjust the position of fixtures to meet the efficient automatic loading and unloading operations of all joints.

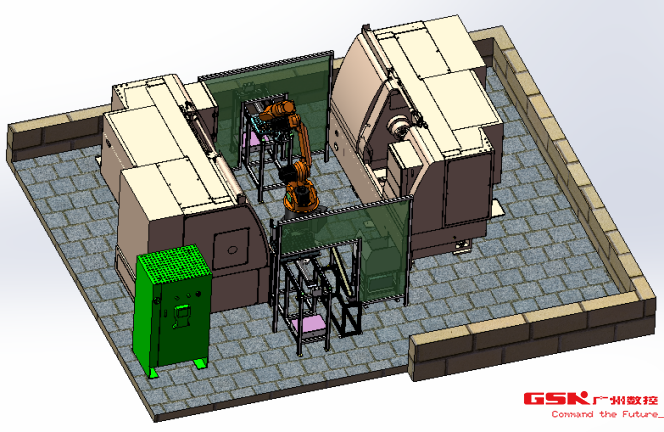

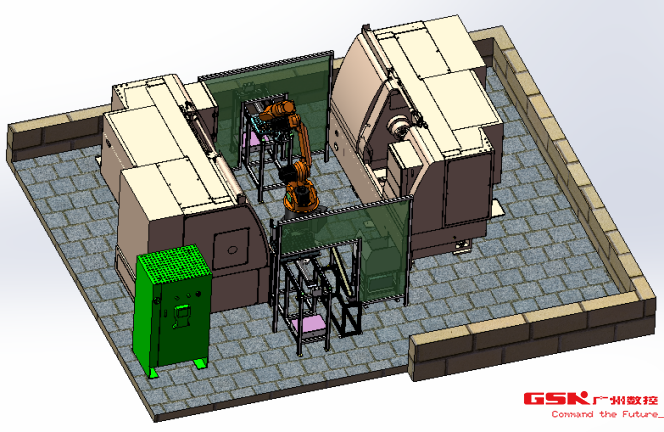

Layout and model application effect

It is very convenient to change the model of the robot loading and unloading system, and one robot replaces the 4 manual machine tool loading and unloading tasks, saving the labor input of machine tool operators; the robot 1 to 2 H-shaped layout is adopted, and the entire system layout It is compact and has high space utilization; the robot loading and unloading system is convenient for changing models, and the production cycle of the entire robot grinding system is closely coordinated, and the operation is stable and smooth; it has achieved long-term stable production, reduced manual labor for boxing, and greatly improved product quality. production capacity.

Application site map

Dongguan Hypertron Intelligent Technology Co., Ltd

specializes in the production of special manipulators for injection molding machines and other automation equipment, spot welding robots, handling robots, general-purpose robots, and spraying robots, which can improve automatic productivity, production stability, production efficiency and Quality, and appropriately reduce production personnel, so that the injection molding production plant has a more competitive advantage in the market.The company provides customers with the best overall automation solutions and services from product planning and design, manufacturing, assembly, sales, and service, and is widely used in electronics, communications, automobiles, home appliances and other fields.Provide high-quality, high-efficiency, and reasonably priced automation products for the plastic industry.

Agent for precision CNC lathes CNC milling CNCmachines grinding machines

General items: research and development of intelligent robots; manufacturing of industrial robots; installation and maintenance of industrial robots; sales of industrial robots; sales of intelligent basic manufacturing equipment; manufacturing of intelligent basic manufacturing equipment; manufacturing of industrial automatic control system devices; sales of industrial automatic control system devices; Manufacturing; sales of intelligent instruments and meters; manufacturing of power electronic components; sales of power electronic components; general mechanical equipment installation services; network and information security software development; Import and export of goods; import and export of technology.

Kennethchui Engineer

13715334662

WeChat ID: kennethchui88

Email: everwinmold@163.com

QQ: 2819840570

Product Image