Product Description

GSK RB50 industrial robot unpacking and loading automation solution

■Customer Requirements

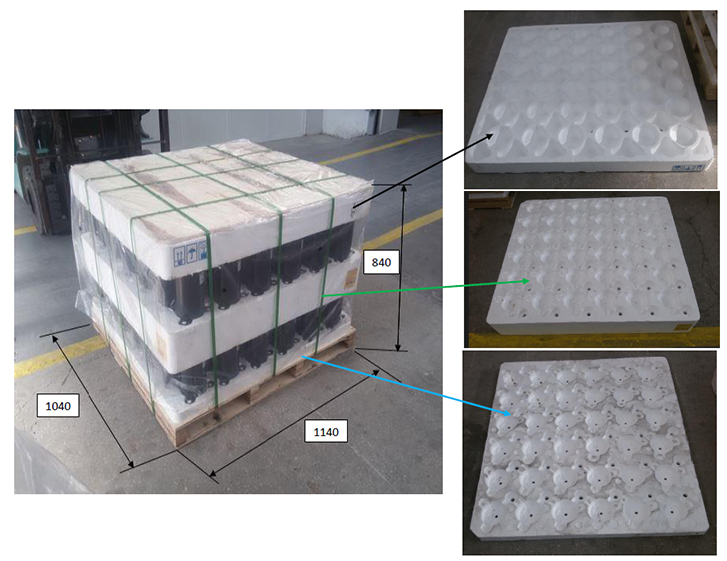

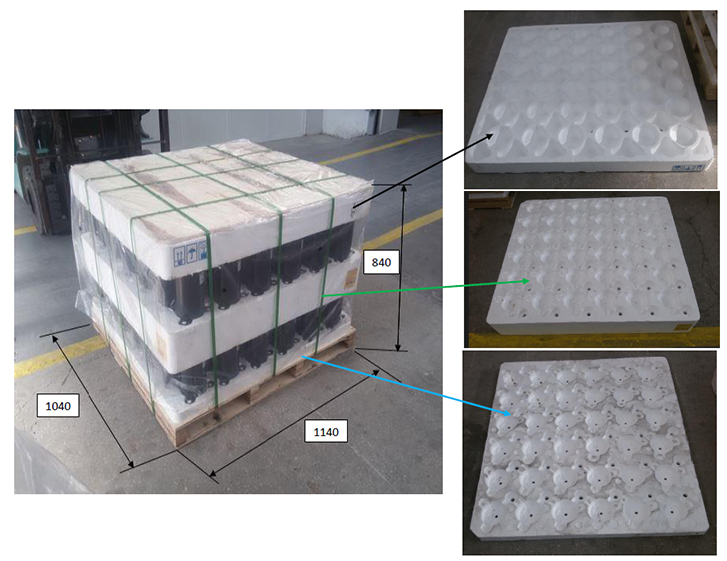

1. Manual one-pallet air-conditioning compressor incoming material (stacking style)

2. After the RB50 robot passes visual recognition, it will be transported to the positioning plate of the conveyor line.

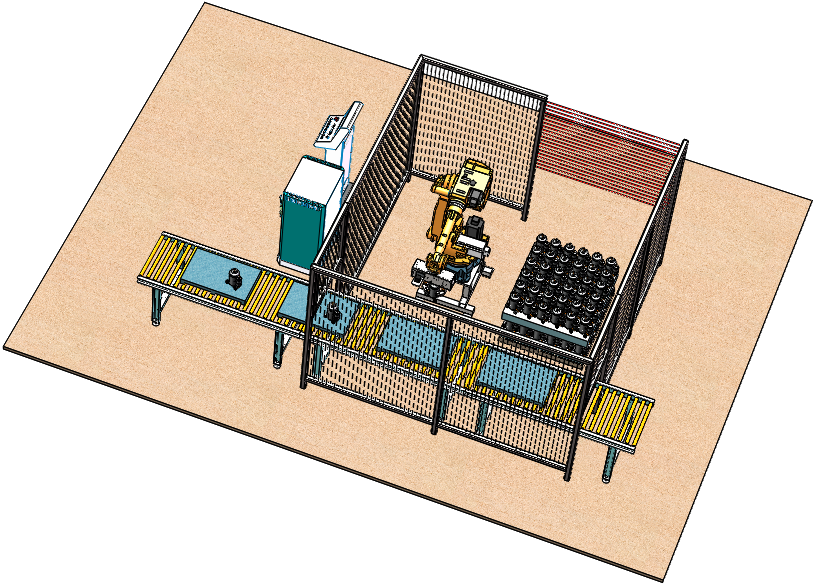

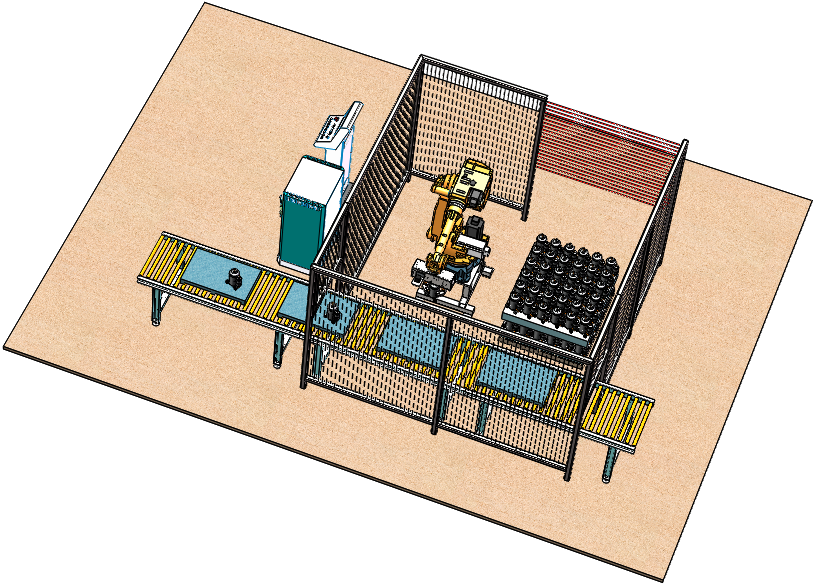

■Scheme layout

■Program description 1. Pick-up gripper (including vision system): Pneumatic control is used to clamp the product, which meets the project requirements for the picking and handling of four specifications of products.Equipped with a CCD industrial camera, it can visually take pictures and locate the parts when picking up and putting them down, and guide the robot to accurately grab and place the compressor products.2. Control system: The whole set of equipment is controlled by the PLC system as a whole. The PLC control system and the robot's own I/O perform signal transfer (including sensors, cables, and main electric control cabinets). The working status and parameters of the equipment.3. Conveyor line (existed by the customer): roller conveying, automatic transport positioning, with installation of cylinder blocking device, detection switch, etc.4. Pallet positioning device: assists in manually placing the pallet to the designated position.5. Safety fence: The working area of the robot is equipped with a protective fence, which is welded with high-quality mesh, and the surface is baked with yellow warning paint. It is also equipped with a safety grating or a safety door lock. When someone enters, the machine will automatically stop to ensure the safety of personnel.

■Program description 1. Pick-up gripper (including vision system): Pneumatic control is used to clamp the product, which meets the project requirements for the picking and handling of four specifications of products.Equipped with a CCD industrial camera, it can visually take pictures and locate the parts when picking up and putting them down, and guide the robot to accurately grab and place the compressor products.2. Control system: The whole set of equipment is controlled by the PLC system as a whole. The PLC control system and the robot's own I/O perform signal transfer (including sensors, cables, and main electric control cabinets). The working status and parameters of the equipment.3. Conveyor line (existed by the customer): roller conveying, automatic transport positioning, with installation of cylinder blocking device, detection switch, etc.4. Pallet positioning device: assists in manually placing the pallet to the designated position.5. Safety fence: The working area of the robot is equipped with a protective fence, which is welded with high-quality mesh, and the surface is baked with yellow warning paint. It is also equipped with a safety grating or a safety door lock. When someone enters, the machine will automatically stop to ensure the safety of personnel.

Dongguan Hypertron Intelligent Technology Co., Ltd

specializes in the production of special manipulators for injection molding machines and other automation equipment, spot welding robots, handling robots, general-purpose robots, and spraying robots, which can improve automatic productivity, production stability, production efficiency and Quality, and appropriately reduce production personnel, so that the injection molding production plant has a more competitive advantage in the market.The company provides customers with the best overall automation solutions and services from product planning and design, manufacturing, assembly, sales, and service, and is widely used in electronics, communications, automobiles, home appliances and other fields.Provide high-quality, high-efficiency, and reasonably priced automation products for the plastic industry.

Agent for precision CNC lathes CNC milling CNCmachines grinding machines

General items: research and development of intelligent robots; manufacturing of industrial robots; installation and maintenance of industrial robots; sales of industrial robots; sales of intelligent basic manufacturing equipment; manufacturing of intelligent basic manufacturing equipment; manufacturing of industrial automatic control system devices; sales of industrial automatic control system devices; Manufacturing; sales of intelligent instruments and meters; manufacturing of power electronic components; sales of power electronic components; general mechanical equipment installation services; network and information security software development; Import and export of goods; import and export of technology.

Kennethchui Engineer

13715334662

WeChat ID: kennethchui88

Email: everwinmold@163.com

QQ: 2819840570

Product Image

■Program description 1. Pick-up gripper (including vision system): Pneumatic control is used to clamp the product, which meets the project requirements for the picking and handling of four specifications of products.Equipped with a CCD industrial camera, it can visually take pictures and locate the parts when picking up and putting them down, and guide the robot to accurately grab and place the compressor products.2. Control system: The whole set of equipment is controlled by the PLC system as a whole. The PLC control system and the robot's own I/O perform signal transfer (including sensors, cables, and main electric control cabinets). The working status and parameters of the equipment.3. Conveyor line (existed by the customer): roller conveying, automatic transport positioning, with installation of cylinder blocking device, detection switch, etc.4. Pallet positioning device: assists in manually placing the pallet to the designated position.5. Safety fence: The working area of the robot is equipped with a protective fence, which is welded with high-quality mesh, and the surface is baked with yellow warning paint. It is also equipped with a safety grating or a safety door lock. When someone enters, the machine will automatically stop to ensure the safety of personnel.

■Program description 1. Pick-up gripper (including vision system): Pneumatic control is used to clamp the product, which meets the project requirements for the picking and handling of four specifications of products.Equipped with a CCD industrial camera, it can visually take pictures and locate the parts when picking up and putting them down, and guide the robot to accurately grab and place the compressor products.2. Control system: The whole set of equipment is controlled by the PLC system as a whole. The PLC control system and the robot's own I/O perform signal transfer (including sensors, cables, and main electric control cabinets). The working status and parameters of the equipment.3. Conveyor line (existed by the customer): roller conveying, automatic transport positioning, with installation of cylinder blocking device, detection switch, etc.4. Pallet positioning device: assists in manually placing the pallet to the designated position.5. Safety fence: The working area of the robot is equipped with a protective fence, which is welded with high-quality mesh, and the surface is baked with yellow warning paint. It is also equipped with a safety grating or a safety door lock. When someone enters, the machine will automatically stop to ensure the safety of personnel.