Product Description

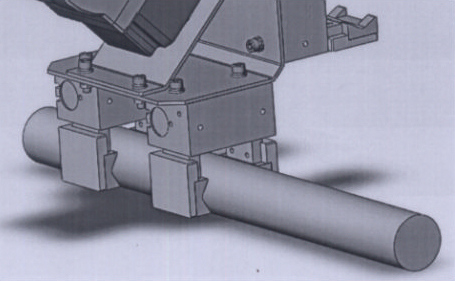

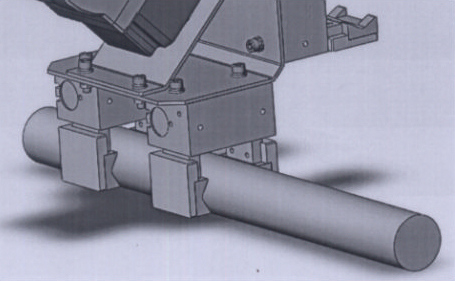

GSK RB08 handling robot application of loading and unloading on the motor shaft

The workpiece required by the customer is a motor shaft with a length of 360~490mm and a weight of about 3~6kg; the processing cycle of the production line is within 140s, that is, a production line produces 1 finished product in 70s on average; the working process is guaranteed to be stable, safe and reliable.Application effect The storage rack can hold 180 pieces of MS100L blank rods at a time, which can meet the continuous processing of about 3 hours. It does not need to be adjusted to replace rods with the same diameter and different specifications. It only needs a slight adjustment to replace rods with different diameters; The material rack is driven by a motor, and the distribution wheel runs and brings the billet to the robot's feeding position to feed the robot. If the sensor detects no material within one minute, the motor will stop and a warning signal will be sent to remind the worker to add materials to the bin. , The whole machine is equipped with multiple protections, safe and reliable; the production program is based on 26 days per month, 2 shifts of 16 hours per day, calculated according to the processing time of MS100L parts, a finished product is produced within 65 seconds, and the monthly output is more than 18,000 pieces.Fully meet customer requirements.

| Model |

RB08 |

| |

| DOF |

6 |

| Drive ModeAC Servo Drive |

|

Payload

(kg)

|

8 |

|

Repeatability

(mm)

|

±0.05 |

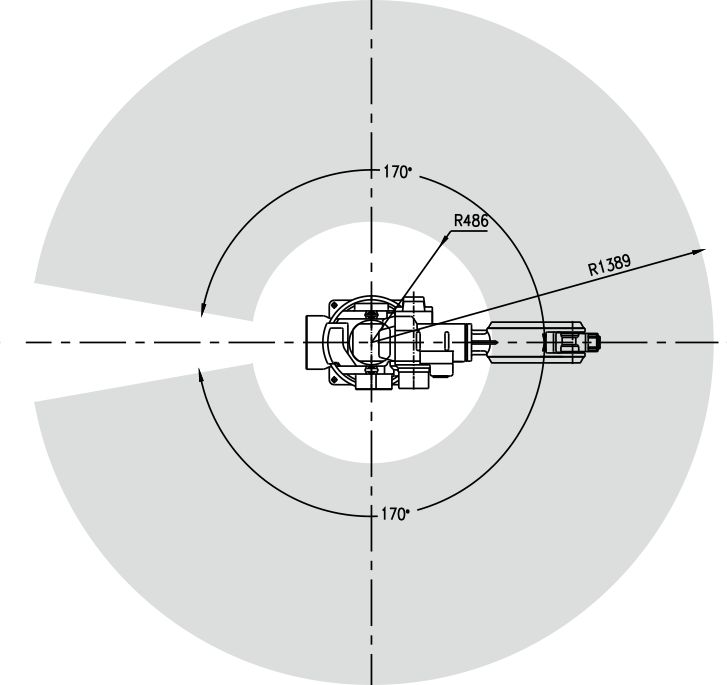

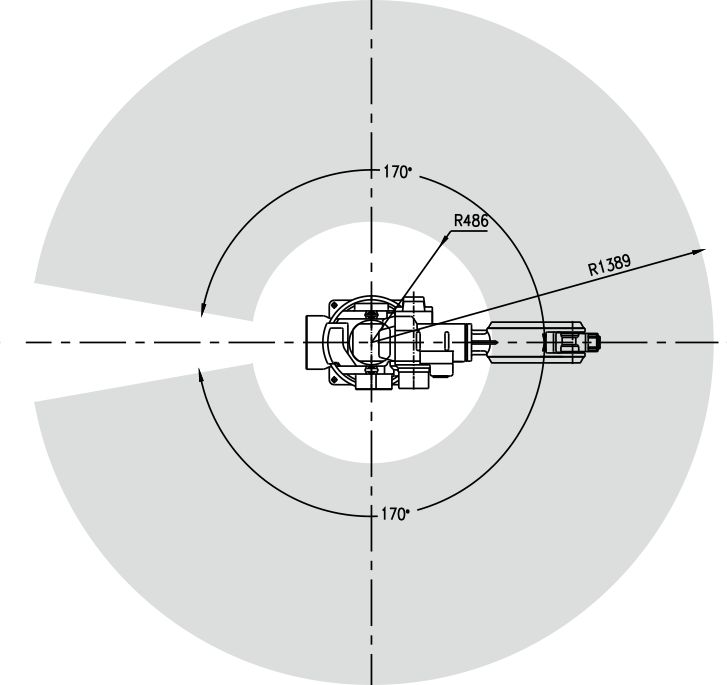

| Range of motion (°) |

J1 |

±170 |

| J2 |

+120~-85 |

| J3 |

+75~-155 |

| J4 |

±180 |

| J5 |

±135 |

| J6 |

±360 |

| Maximum speed(°/s) |

J1 |

154 |

| J2 |

154 |

| J3 |

154 |

| J4 |

420 |

| J5 |

252 |

| J6 |

620 |

|

Allowable maximum torque

(N.m)

|

J4 |

14 |

| J5 |

12 |

| J6 |

7 |

|

radius of motion

(mm)

|

1389 |

|

body weight

(kg)

|

180 |

Widely used in logistics handling, machine tool loading and unloading, stamping automation, assembly, grinding, polishing, etc.

Dongguan Hypertron Intelligent Technology Co., Ltd

specializes in the production of special manipulators for injection molding machines and other automation equipment, spot welding robots, handling robots, general-purpose robots, and spraying robots, which can improve automatic productivity, production stability, production efficiency and Quality, and appropriately reduce production personnel, so that the injection molding production plant has a more competitive advantage in the market.The company provides customers with the best overall automation solutions and services from product planning and design, manufacturing, assembly, sales, and service, and is widely used in electronics, communications, automobiles, home appliances and other fields.Provide high-quality, high-efficiency, and reasonably priced automation products for the plastic industry.

Agent for precision CNC lathes CNC milling CNCmachines grinding machines

General items: research and development of intelligent robots; manufacturing of industrial robots; installation and maintenance of industrial robots; sales of industrial robots; sales of intelligent basic manufacturing equipment; manufacturing of intelligent basic manufacturing equipment; manufacturing of industrial automatic control system devices; sales of industrial automatic control system devices; Manufacturing; sales of intelligent instruments and meters; manufacturing of power electronic components; sales of power electronic components; general mechanical equipment installation services; network and information security software development; Import and export of goods; import and export of technology.

Kennethchui Engineer

13715334662

WeChat ID: kennethchui88

Email: everwinmold@163.com

QQ: 2819840570

Product Image