Product Description

GSK RB08 handling robot application of loading and unloading disk parts

The customer requires one RB08 robot, two CNC lathes, and one automatic loading and unloading auxiliary equipment to form a robot lathe loading and unloading system; it can follow the production rhythm of the workpiece to ensure the production efficiency and the safety, stability and reliability of the working process; when the robot is powered off , When the air is cut off, the workpiece picked up by the gripper cannot be loosened or fallen off, and the gripper has a position confirmation switch; the loading and unloading system needs to have strong flexibility, which can be used for automatic loading and unloading of various workpieces.Application Effect This set of solutions is designed with economy, safety, good operability, and reliability as the design criteria, and has high flexibility. It can be applied to customers only by making slight adjustments to the rotary feeder and robot gripper. The loading and unloading processing of the four parts provided; robot output, lathe input, the robot outputs this signal after entering the lathe, the lathe receives the signal interlock and prohibits the movement of all motion mechanisms, and resets the signal until the robot completely exits the lathe to ensure that the robot It is safe and reliable to cooperate with the machine tool; the control system has soft/hard limit, control abnormality, emergency stop and other fault display and alarm functions. When the robot is powered off or out of air, the workpiece picked up by the gripper will not loosen or fall off; The solution can be run in three shifts a day, and workers can provide sufficient blanks to achieve continuous processing and improve production efficiency.

| Model |

RB08 |

| |

| DOF |

6 |

| Drive ModeAC Servo Drive |

|

Payload

(kg)

|

8 |

|

Repeatability

(mm)

|

±0.05 |

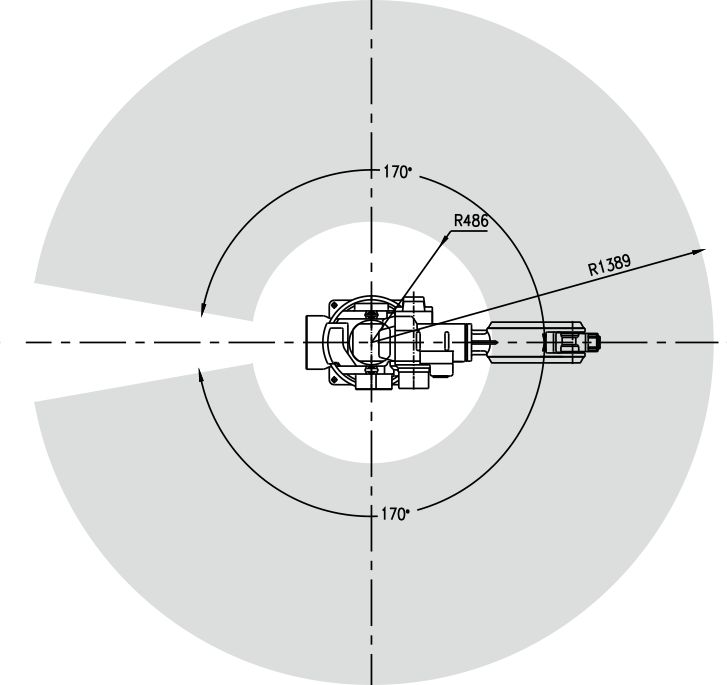

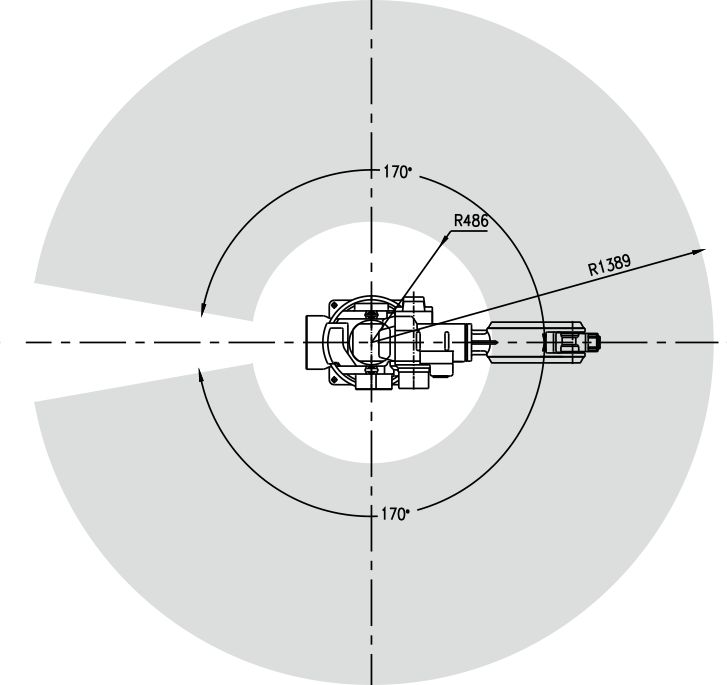

| Range of motion (°) |

J1 |

±170 |

| J2 |

+120~-85 |

| J3 |

+75~-155 |

| J4 |

±180 |

| J5 |

±135 |

| J6 |

±360 |

| Maximum speed(°/s) |

J1 |

154 |

| J2 |

154 |

| J3 |

154 |

| J4 |

420 |

| J5 |

252 |

| J6 |

620 |

|

Allowable maximum torque

(N.m)

|

J4 |

14 |

| J5 |

12 |

| J6 |

7 |

|

radius of motion

(mm)

|

1389 |

|

body weight

(kg)

|

180 |

Widely used in logistics handling, machine tool loading and unloading, stamping automation, assembly, grinding, polishing, etc.

Dongguan Hypertron Intelligent Technology Co., Ltd

specializes in the production of special manipulators for injection molding machines and other automation equipment, spot welding robots, handling robots, general-purpose robots, and spraying robots, which can improve automatic productivity, production stability, production efficiency and Quality, and appropriately reduce production personnel, so that the injection molding production plant has a more competitive advantage in the market.The company provides customers with the best overall automation solutions and services from product planning and design, manufacturing, assembly, sales, and service, and is widely used in electronics, communications, automobiles, home appliances and other fields.Provide high-quality, high-efficiency, and reasonably priced automation products for the plastic industry.

Agent for precision CNC lathes CNC milling CNCmachines grinding machines

General items: research and development of intelligent robots; manufacturing of industrial robots; installation and maintenance of industrial robots; sales of industrial robots; sales of intelligent basic manufacturing equipment; manufacturing of intelligent basic manufacturing equipment; manufacturing of industrial automatic control system devices; sales of industrial automatic control system devices; Manufacturing; sales of intelligent instruments and meters; manufacturing of power electronic components; sales of power electronic components; general mechanical equipment installation services; network and information security software development; Import and export of goods; import and export of technology.

Kennethchui Engineer

13715334662

WeChat ID: kennethchui88

Email: everwinmold@163.com

QQ: 2819840570

Product Image