Product Description

GSK AE100 injection molding machine in auto parts automobile transmission worm gear

.jpg)

Application field: auto parts---automobile transmission worm gear

Applied material: Nylon + 30% fiber

Size requirements: concentricity 0.05mm, diameter tolerance of inner and outer circles 0.02mm

Performance requirements: more accurate transmission of motion, constant transmission ratio, smooth motion, to reduce impact, vibration and noise, tooth surface contact should be uniform

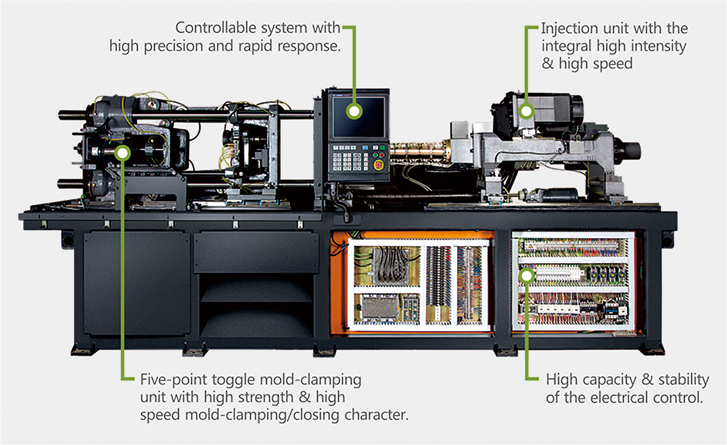

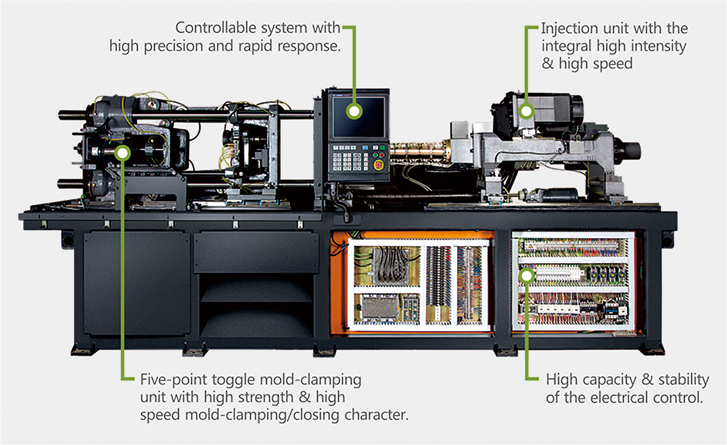

GSK AE100 Full Electric Injection Molding Machine

AE Series Full Electric Injection Molding Machine is absolutely Researched and Developed by GSK CNC EQUIPMENT CO., LTD, which is the technology essence for devoting the mechanical design and servo control for many years. It owns the advantages, such as the precision, high-speed, energy-saving and environmental protection, etc., which can be widely used in the electron & communication, optics, medical treatment, food and consumable goods, etc. The core components, for example, mechanical body, controllable system, servo motor, drive and big loading ball screw, are absolutely researched and developed by GSK, so that the AE series full electric injection molding machine can be provided the strong guarantee for forming your product, as well met your characteristic requirements.

Mold-clamping unit

.png)

.png)

.png)

Injection unit

.png)

.png)

.png)

GSK 6000 controller

.png)

Realize the green energy-saving of GSK servo system

.png)

.png)

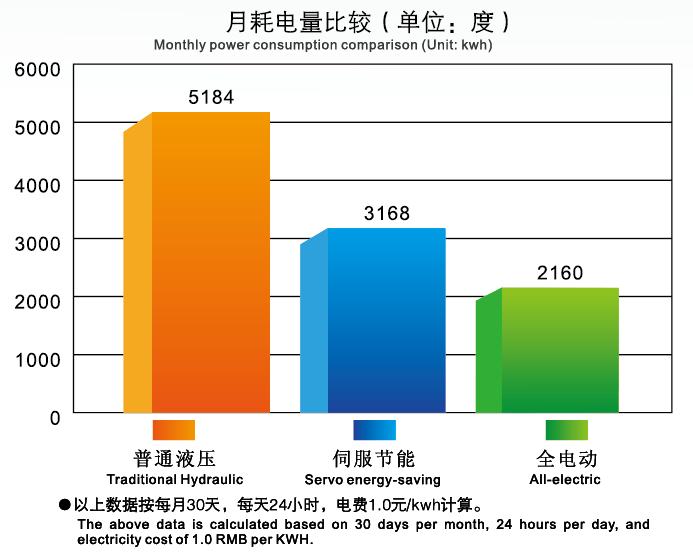

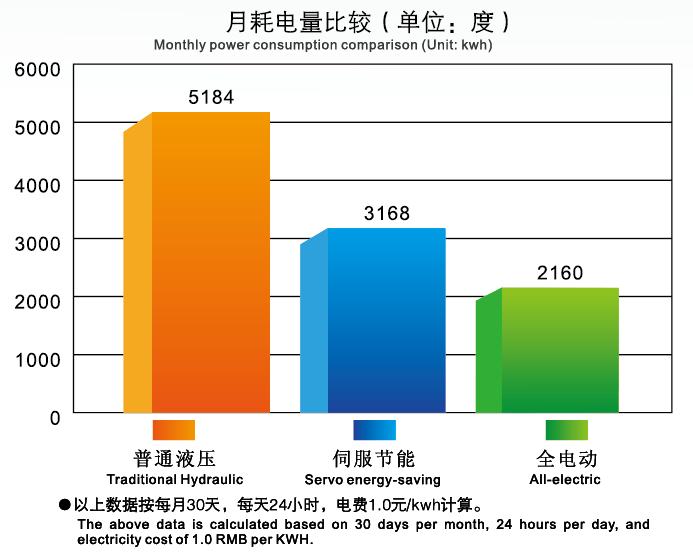

Energy-Saving

AE Series Full-Electric Injection Molding Machine can be saved up to 70% electric energy compared with the traditional ratio pump hydraulic vone regardless of the oil cooling simultaneously; up to 90% water resource can be saved accordingly.

Green & Environmental-Protection

1.It drives by servo motor regardless of the pollution issue for the environment by the hydraulic oil; it also provides cleaning production surroundings for the customers.

2.The accuracy lubrication that can be performed by tin filling grease pump matches with the qualification metering; the machine can be held cleaning in a large extent.

| Type |

AE100 |

| Injection&plasticizing unit |

Shoot machine model |

|

S250 |

S280 |

S320 |

| The screw diameter |

mm |

25 |

28 |

32 |

28 |

32 |

36 |

32 |

36 |

40 |

| The theory of injection capacity |

cm3 |

54 |

67 |

88 |

77 |

100 |

127 |

121 |

153 |

188 |

| Theory of injection weight(PS) |

g |

51 |

64 |

84 |

73 |

95 |

121 |

115 |

146 |

179 |

| The maximum injection pressure |

Mpa |

277 |

221 |

169 |

287 |

220 |

173 |

272 |

215 |

174 |

| The maximum pressure maintaining pressure |

Mpa |

220 |

176 |

135 |

230 |

176 |

138 |

218 |

172 |

140 |

| The injection rate |

cm3/s |

167 |

209 |

273 |

185 |

240 |

305 |

241 |

305 |

377 |

| The largest injection speed |

mm/s |

340 |

300 |

300 |

| The injection stroke |

mm |

110 |

125 |

150 |

| The screw rotation speed |

rpm |

0-350 |

0-350 |

0-350 |

| Nozzle outstanding amount |

mm |

35 (70) |

35 (70) |

35 (70) |

| Plasticizing capacity(PS) |

Kg/h |

27 |

36 |

52 |

41 |

61 |

84 |

59 |

78 |

106 |

| Nozzle contact force |

kN |

12 |

| The temperature control section number |

|

5 |

| Total heating power |

kw |

4.7 |

5.6 |

6.2 |

5.6 |

6.8 |

7.7 |

8 |

8.9 |

10.4 |

| Clamping unit |

Clamping way |

|

|

| Clamping force |

ton |

100 |

| Drive travel |

mm |

350 |

| The minimum thickness of the mould |

mm |

200 |

| The biggest mould thickness |

mm |

410 |

| Elder brother Lin Zhu spacing (length X height) |

mm |

460X410 |

| Minimum mould size (length X height) |

mm |

325X325 |

| Ejecting force |

kN |

25 |

| Ejection stroke |

mm |

100 |

| Number of thimble |

|

5 |

| Other information |

Overall dimensions (length X width X height) |

m |

4.85X1.28X2.24 |

| Machine weight |

t |

5.3 |

5.4 |

5.5 |

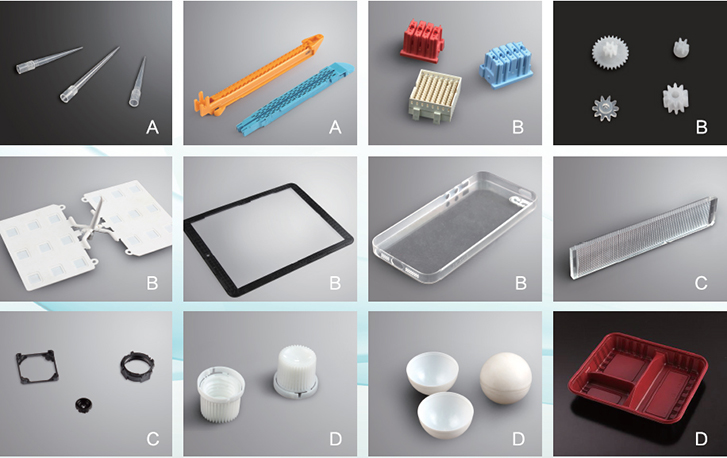

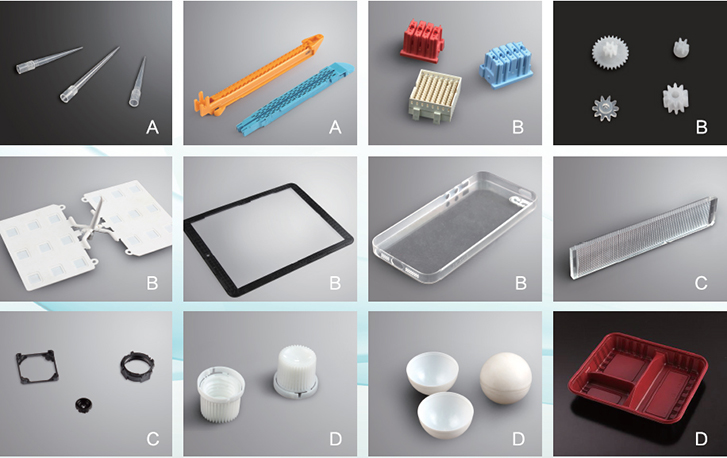

Medical Industry

Medical Industry

DNA detection tube, medical plug-in, hearing-aid……

Electron& Communication

Connector, mobile phone shell, computer frame……

Optical Industry

Mobile phone lens, light guide plate …

Food Industry

Container, bottle cap for fresh-keeping……

Dongguan Hypertron Intelligent Technology Co., Ltd

specializes in the production of special manipulators for injection molding machines and other automation equipment, spot welding robots, handling robots, general-purpose robots, and spraying robots, which can improve automatic productivity, production stability, production efficiency and Quality, and appropriately reduce production personnel, so that the injection molding production plant has a more competitive advantage in the market.The company provides customers with the best overall automation solutions and services from product planning and design, manufacturing, assembly, sales, and service, and is widely used in electronics, communications, automobiles, home appliances and other fields.Provide high-quality, high-efficiency, and reasonably priced automation products for the plastic industry.

General items: research and development of intelligent robots; manufacturing of industrial robots; installation and maintenance of industrial robots; sales of industrial robots; sales of intelligent basic manufacturing equipment; manufacturing of intelligent basic manufacturing equipment; manufacturing of industrial automatic control system devices; sales of industrial automatic control system devices; Manufacturing; sales of intelligent instruments and meters; manufacturing of power electronic components; sales of power electronic components; general mechanical equipment installation services; network and information security software development; Import and export of goods; import and export of technology.

Kennethchui Engineer

13715334662

WeChat ID: kennethchui88

Email: everwinmold@163.com

QQ: 2819840570

Product Image

.jpg)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)