Five-axis servo manipulator BRTV09WDS5P0/F0 BRTV09WDS5P0/F0 series is suitable for taking out finished products and nozzles of various types of horizontal injection machines from 120T to 320T. The tail end of the machine can save the installation space of the machine.The arm form is double section, double arm, up and down stroke 900mm, five-axis AC servo drive, the installation can save the installation space of the injection machine by 30-40%, make full use of the factory building, and increase the production capacity (20-30%), reduce the product The defect rate is high, the safety of operators is guaranteed, labor is reduced, production volume is accurately controlled, and waste is reduced.Five-axis drive and control integrated control system: fewer signal lines, long-distance communication, good expansion performance, strong anti-interference ability, high repeat positioning accuracy, simultaneous control of multiple axes, simple equipment maintenance, and low failure rate.

Main Specification

| Power capacity (KVA) |

Applicable molding machine (ton) |

Drive method |

Fixture type |

| 3.5 |

120T-320T |

AC servo motor |

Two suction and two holding |

| Traversing stroke (mm) |

Pulling stroke (mm) |

Up and down stroke (mm) |

Maximum load (KG) |

| The total length of the horizontal arch is within 6 meters |

to be determined |

900 |

5 |

| Take out time (sec) |

Full cycle time (sec) |

Release angle (degree) |

Air consumption ( NI/cycle) |

| 1.7 |

To be determined |

undefined |

9 |

| Weight (KG) |

| non-standard |

Denote: W Telescopic type D: Product arm + runner arm S1: AC Servo driven on traverse axis

The above-mentioned cycle time are the results of our internal test standard. In the actual application process of the machine,they will vary according to the actual operation

| A |

B |

C |

D |

E |

| 1555 |

less than 6 meters |

160 |

to be determined |

to be determined |

| F |

G |

H |

I |

J |

| to be determined |

174 |

187 |

to be determined |

to be determined |

| K |

L |

M |

N |

O |

| 126 |

266 |

to be determined |

549 |

484 |

| P |

Q |

| to be determined |

900 |

Dongguan Hypertron Intelligent Technology Co., Ltd

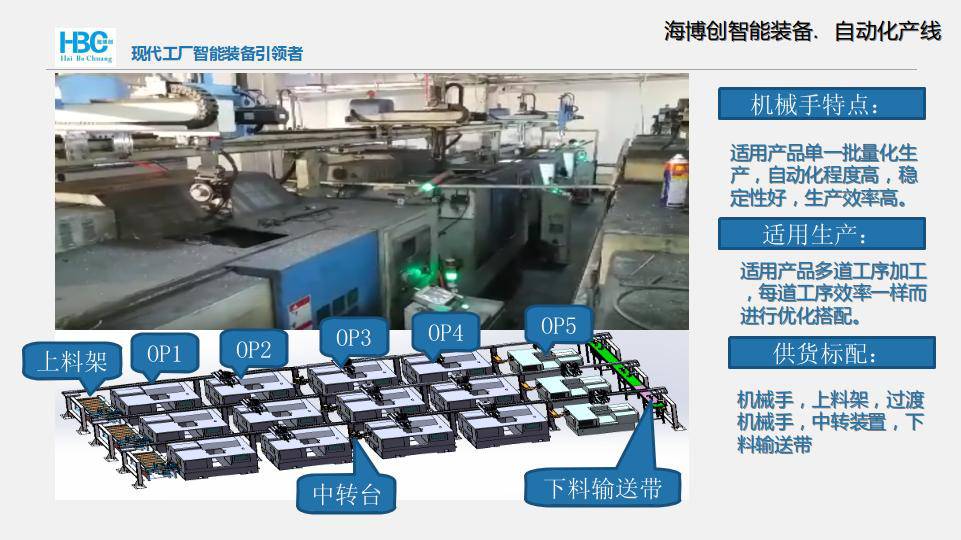

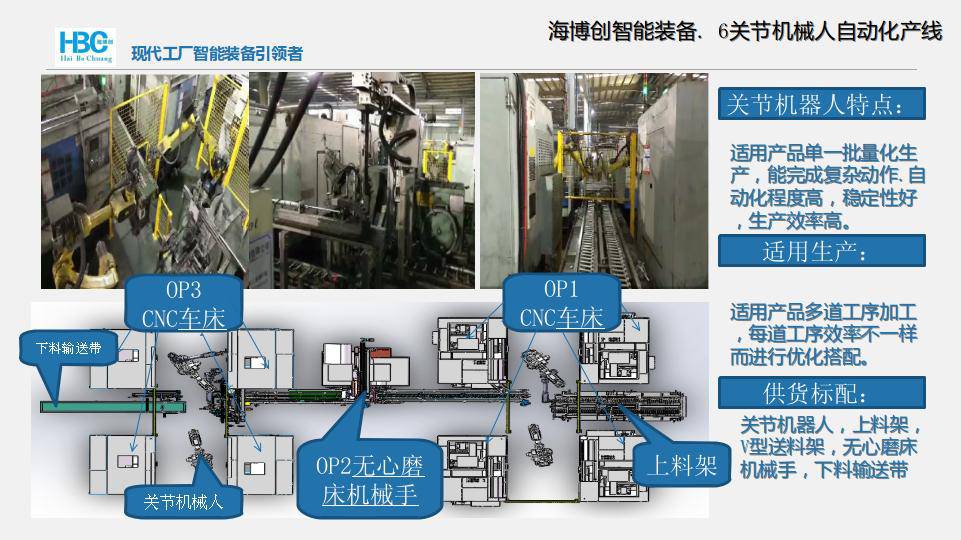

specializes in the production of special manipulators for injection molding machines and other automation equipment, spot welding robots, handling robots, general-purpose robots, and spraying robots, which can improve automatic productivity, production stability, production efficiency and Quality, and appropriately reduce production personnel, so that the injection molding production plant has a more competitive advantage in the market.The company provides customers with the best overall automation solutions and services from product planning and design, manufacturing, assembly, sales, and service, and is widely used in electronics, communications, automobiles, home appliances and other fields.Provide high-quality, high-efficiency, and reasonably priced automation products for the plastic industry.

General items: research and development of intelligent robots; manufacturing of industrial robots; installation and maintenance of industrial robots; sales of industrial robots; sales of intelligent basic manufacturing equipment; manufacturing of intelligent basic manufacturing equipment; manufacturing of industrial automatic control system devices; sales of industrial automatic control system devices; Manufacturing; sales of intelligent instruments and meters; manufacturing of power electronic components; sales of power electronic components; general mechanical equipment installation services; network and information security software development; Import and export of goods; import and export of technology.

Kennethchui Engineer

13715334662

WeChat ID: kennethchui88

Email: everwinmold@163.com

QQ: 2819840570