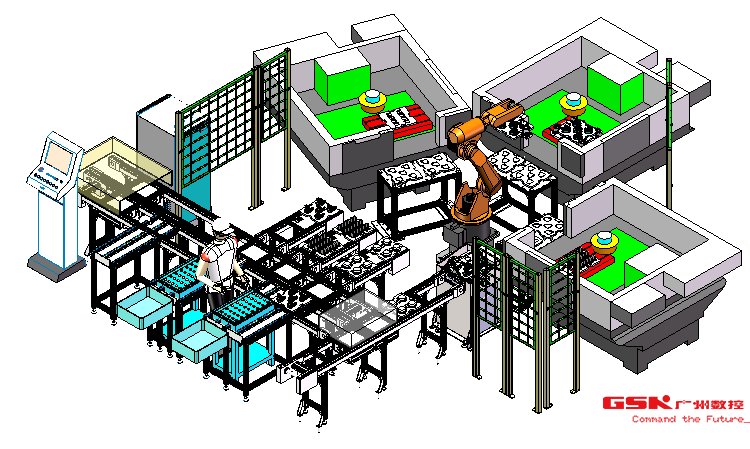

GSK RB15L robot application combined with CNC milling machine, realizes the automatic production of die-casting parts

- The robot replaces manual labor and completes the loading and unloading production of workpieces between 3 CNC milling machines, pallet fixtures, and upper and lower bins; 3 products are mixed up and down at the same time, and special pallets and milling machine processing fixtures are used; robot fixtures are highly versatile and need to achieve mixing of different products Grab the loading and unloading.The processing time of production milling machine is 1-5 minutes, and the production capacity of production line: 350 pieces/hour;

Work object solution

1 set of RB15L handling robot, 1 set of customized flexible gripper, 3 sets of machine tool fixtures, 1 set of split-disk double-speed conveyor line, 3 sets of temporary storage positioning device, 1 set of pallet cleaning device, supporting 3 CNC milling machines, complete The blanks are loaded on separate trays, plane milling, drilling and tapping, cleaning workpieces and centralized collection of finished products off-line; the robot gripper adopts a customized and flexible design, which is compatible with all pallets, precise positioning, and has the function of preventing falling due to abnormal air and power failures , to ensure stable production of loading and unloading.The double-speed chain conveying system is used to sort and convey the pallet fixtures and the pallet turnover cache, which is convenient for workers to collect materials in a centralized manner; the FDI automatic identification system technology is used to automatically sort and convey different pallets, and automatically identify the corresponding loading workers for pallet processing workpieces bit;

The application effect of the model layout

adopts a compatible flexible manipulator design, which solves the problem of multi-model and small-batch production on the same production line with less manufacturing cost; robots replace labor, and realize that 1 to 3 CNC machine tools can work 24 hours at any time, stable Complete the work tasks; the robot operation is closely coordinated with the CNC milling machine and the double-speed chain conveying system, the work is stable, the production efficiency is maximized, and the production and operation costs are reduced.

Application rendering

Dongguan Hypertron Intelligent Technology Co., Ltd

specializes in the production of special manipulators for injection molding machines and other automation equipment, spot welding robots, handling robots, general-purpose robots, and spraying robots, which can improve automatic productivity, production stability, production efficiency and Quality, and appropriately reduce production personnel, so that the injection molding production plant has a more competitive advantage in the market.The company provides customers with the best overall automation solutions and services from product planning and design, manufacturing, assembly, sales, and service, and is widely used in electronics, communications, automobiles, home appliances and other fields.Provide high-quality, high-efficiency, and reasonably priced automation products for the plastic industry.

Agent for precision CNC lathes CNC milling CNCmachines grinding machines

General items: research and development of intelligent robots; manufacturing of industrial robots; installation and maintenance of industrial robots; sales of industrial robots; sales of intelligent basic manufacturing equipment; manufacturing of intelligent basic manufacturing equipment; manufacturing of industrial automatic control system devices; sales of industrial automatic control system devices; Manufacturing; sales of intelligent instruments and meters; manufacturing of power electronic components; sales of power electronic components; general mechanical equipment installation services; network and information security software development; Import and export of goods; import and export of technology.

Kennethchui Engineer

13715334662

WeChat ID: kennethchui88

Email: everwinmold@163.com

QQ: 2819840570